About Infrared Services of Alabama LLC

My Expertise

My Experience & Background

My Experience & Background

My name is Tyler Findlay. I am an engineer with nearly a decade of EXTENSIVE thermographic experience. As a thermographer with a rare Level III Master Thermographer Certification, I have been sought out by several utilities and engineering firms over the years for consultation. My expertise has recently led to the FLIR Infrared Training Center securing my services to teach infrared thermography certification classes.

My Experience & Background

My Experience & Background

My Experience & Background

I worked for Alabama Power Company for over 41 years with the majority of that career spent as a Power Quality engineer and in Energy Services as a Project Manager & Thermographer. During my time in Energy Services, I worked to develop a formal Infrared Inspection Program. Since the program's implementation, I have performed hundreds of infrared inspections for some of the largest industrial and commercial facilities across Alabama and average roughly 75 inspections per year.

Infrared Inspections by Infrared Services of Alabama LLC

Why have an Infrared Inspection?

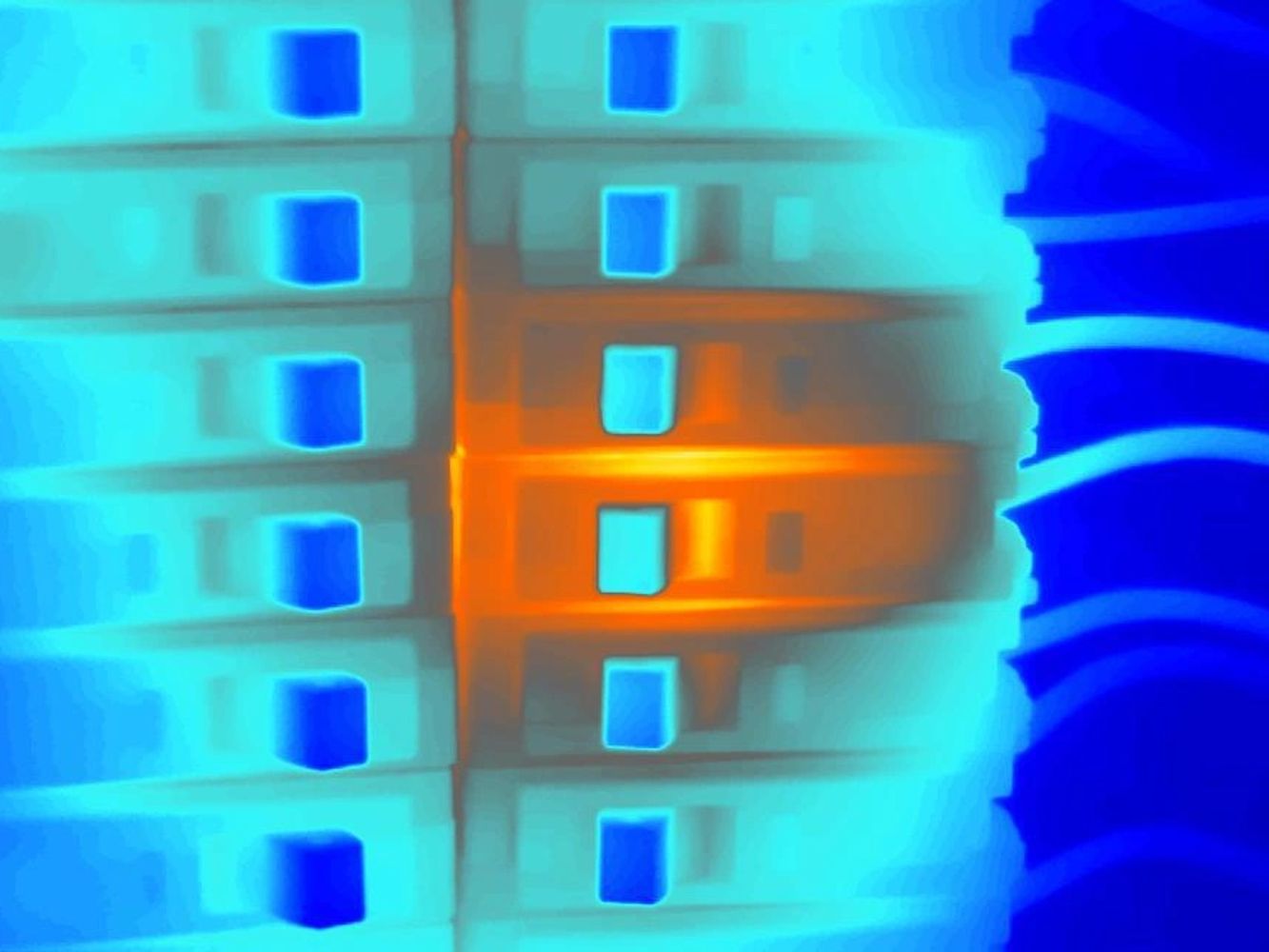

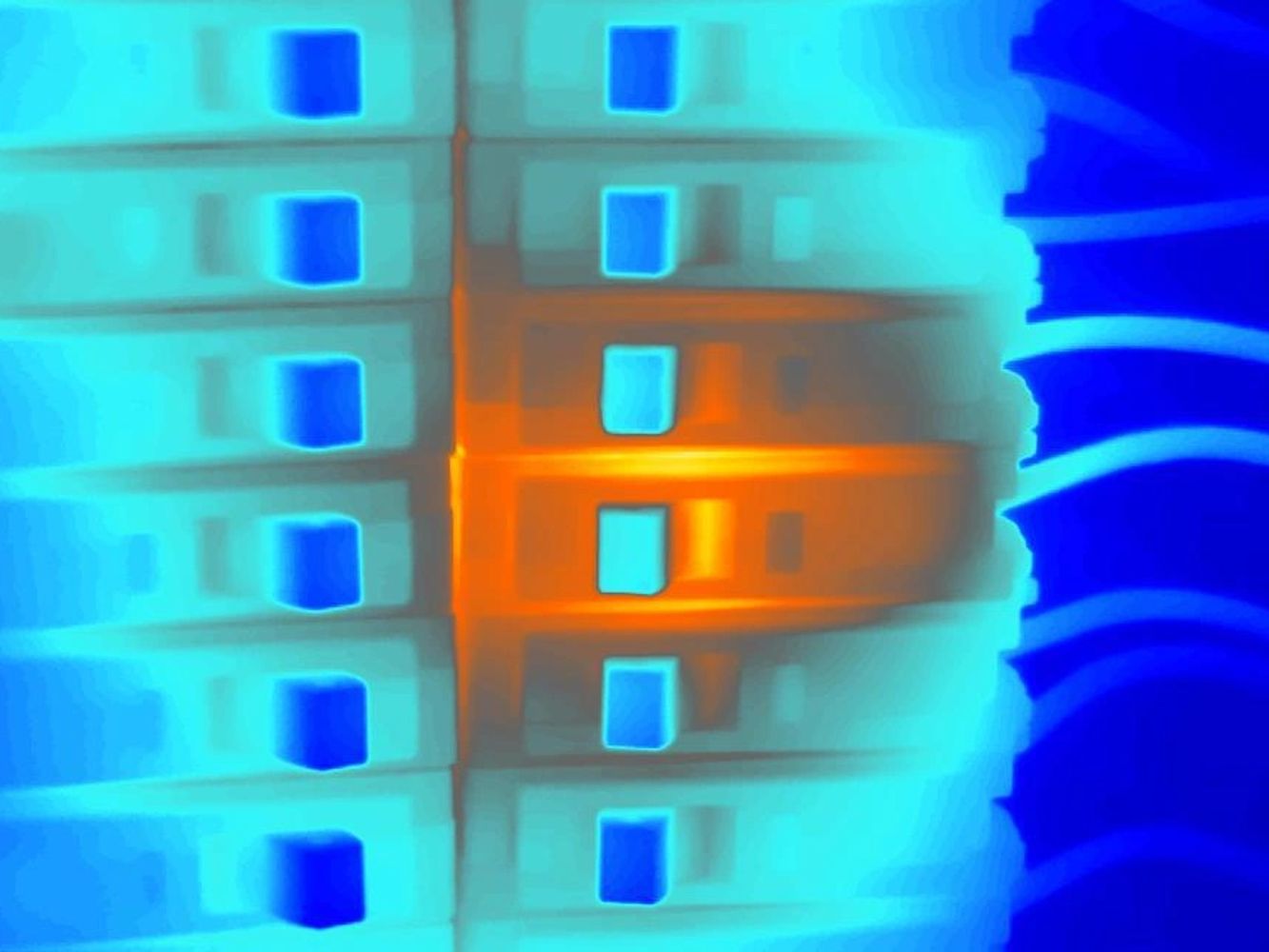

Electrical and electronic equipment and connections can gradually deteriorate due to harsh environments, vibrations, thermal expansion and contraction cycles, overloads, corrosion, defects, or poor installation. This can lead to equipment failure or misoperations, arcing, and even fire. Infrared inspections, or "scans", can spot these problems early in the "failure cycle", saving you from potentially catastrophic equipment failures, arc flash events, and unexpected repair/replacement costs and downtime.

Because an infrared inspection provided by Infrared Services of Alabama LLC would be performed by a Level III Certified Master Thermographer, you might qualify for a discount on your commercial insurance. We encourage you to check with your insurer about that. Also, something else to consider is that the National Fire Protection Association (NFPA) has revised their NFPA 70B 2023 Standard to call for making annual infrared inspections of ALL electrical equipment at all industrial/commercial facilities "mandatory". (See more detail on NFPA 70B below.)

Infrared Inspections by Infrared Services of Alabama LLC

Advantages of Using Infrared Services of Alabama LLC

- Highly qualified and experienced thermographer with an ITC Level III Master Thermographer Certification (FLIR Certificate # 148269025)

- High resolution FLIR infrared camera

- Detailed exceptions report provided with suggested corrections and recommended timeline for corrections

- Thermographer is equipped with proper PPE including arc flash rated clothing and has decades of experience working around energized, exposed electrical equipment

Customer Requirements:

- Customer will need to provide an escort(s) qualified to uncover the electrical equipment to provide line of sight exposure to the electrical connections in the equipment being inspected (unless precluded by arc flash considerations). This escort can be facility maintenance personnel or a commercial electrical contractor, but they should preferably be familiar with the facility electrical equipment. Please Note: If you need to secure an electrical contractor to perform this function, I now have an affiliation with Trinity Contractors, a commercial electrical contractor, and they can provide this function if needed.

- We suggest the customer determine ahead of time exactly what equipment they want inspected and compile an inventory of items to be inspected. The escort should be supplied with this information (and any uncertainties resolved) before beginning the inspection, so they can provide clear guidance to the thermographer.

- The escort might be asked to provide ampere readings for reference in analyzing the equipment. We can furnish a suitable ammeter for this.

- The customer will need to insure that the inspection takes place during "normal" production time and the facility is operating at as close to maximally as possible in order to get the most benefit from an infrared inspection. Equipment that is not operating or in service will not be able to be inspected.

About the 2023 NFPA 70B Standard

Background about the NFPA 70B Standard

Every few years, the National Fire Protection Association (NFPA) updates the NFPA 70B Standard (Standard for Electrical Equipment Maintenance) which is a set of guidelines for developing electrical preventive maintenance (EPM) programs for industrial and commercial facilities.

This Standard drives EPM decisions and development. NFPA 70B details electrical inspection methods, what equipment should be inspected, and who is qualified to carry out these inspections.

The previous NFPA 70B version "recommended" infrared scanning be conducted annually on certain electrical equipment.

What's the big change with the 2023 NFPA 70B revision?

The 2023 NFPA 70B Standard now makes mandatory the inspection of ALL electrical equipment at least once a year. It also calls for some equipment to be inspected every 6 months.

Some Key Takeaways from the New NFPA 70B Standard

- Infrared thermographic inspection of electrical equipment shall be performed at least once per year. Although the NFPA has no "enforcement" capability and the new standard is not mandated by law, you need to be aware that NFPA 70B is considered the minimum consensus requirement for safe electrical work practices and the Occupational Safety and Health Administration (OSHA) can utilize the standard to issue citations.

- A key impact for your personnel is that, if they are expected to perform infrared thermography, they must be "qualified to operate the test equipment". In the case of infrared thermography, this would be expected to require procuring infrared cameras, maintaining the cameras (yearly calibrations, maintenance, repairs), and obtaining proper infrared thermography training and certifications. All of that adds up to a fairly costly endeavor.

Frequently Asked Questions

Please reach out to us at (205) 910-6991 if you cannot find an answer to your question.

The National Fire Protection Association (NFPA) has for years suggested that every industrial and commercial facility have an infrared inspection performed at least once per year. With the 2023 revision of the NFPA Standard 70B, the NFPA now "mandates" that every industrial and commercial facility have all of their electrical equipment inspected at least once per year. (See more information on the 2023 NFPA Standard 70B above.)

No! Equipment needs to be on and running at normal levels when an infrared inspection is performed.

Equipment inspected typically includes the main switchgear and switchboards, distribution panels, lighting panels, disconnects, contactor cabinets, busways, production equipment control panels, and dry-type transformers. Additionally, for customers that have their own primary distribution system, equipment typically inspected includes poles and associated pole-mounted hardware (switches, capacitors, etc.), padmounted transformers, and switchgear.

Yes. We have the expertise and experience to provide inspections of distribution pole lines, transformers, and substations.

Yes. We would first need to get some details on the facility or facilities to be inspected.